Electrical Infrared Inspections

In any working environment there is a constant requirement to adequately and routinely assess electrical performance.Call Us Today

(866)630-7070

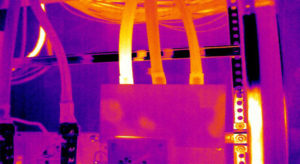

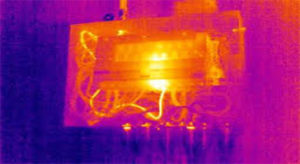

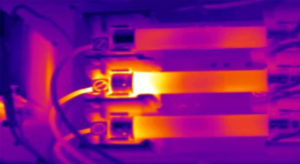

Electrical thermography can be used as a non-invasive tool for routine maintenance, inspecting inaccessible areas or simply to fulfill insurance requirements. Consequently, this allows for the early detection of faults and issues that could otherwise present risks to health and the environment. Reduction or failure within electrical infrastructures can have far reaching consequences creating unnecessary downtime and long term financial impact. Avoiding such eventualities can be easily managed when operating a consistent approach to routine inspection.

- Insurance Requirement – Specifically fulfill your insurance conditions.

- Poor Connections – Allows the early detection of faults.

- Uneven Loading – Prevent a phase imbalance.

Precise Infrared electrical thermography approach is discreet and methodical undertaken during normal working conditions. The resulting report highlights actual rather than perceived areas where an immediate or longer term maintenance plan should be implemented. This level of detail offers the opportunity for more effective management and control of resources, scheduling and expenditure.

Why thermography on electrical systems?

Electrical thermal imaging is the most established application for thermography. Electrical thermography is useful as there is no other preventive maintenance technology or technique that can identify defects such as poor connections, over loaded cables and faulty electrical equipment as safely and as quickly, whilst causing no interruption to the normal operation of your business.

Thermographic Survey Approach and Reporting Structure

Our survey approach has been tailored over many years to ensure thermographic inspections are carried out safely and non-intrusively, causing no disruption to business operations whilst providing a full audit trail of the health of the equipment that has been inspected.

Working with insurance companies, safety risk assessors and Engineering Maintenance Managers, our thermographic survey reports have been developed to satisfy strict standards ensuring that expectations from the thermographic inspection and survey report are fully met.

Thermographic Survey reports are structured as follows:

- Introduction/Report Summary – This provides detail on the survey carried out together a top level summary of the overall findings.

- Main Body Report Pages – Where faults/anomalies are identified, an individual report page is produced providing a description of the fault, its severity and recommended remedial action.

- Appendices – These pages provide a checklist and images of every asset inspected during the survey. This provides an auditable record of what was inspected, together with equipment health at the time of the survey.

Please contact us if you require a sample report.